Condition Monitoring puts you in control of your maintenance schedule, allowing you to be proactive regarding your outage times rather than reacting to costly breakdowns. By regularly recording and analysing operational data, equipment health can be assessed in order to plan the allocation of maintenance resources when and where they are required.

This process can make a substantial contribution to the optimisation and management of your equipment and plant, which aids in achieving the optimal usage rate of the equipment and gives you the control to plan maintenance and ensure downtime minimisation.

Condition monitoring can also be used to perform a root cause analysis, which in sync with our REDU process, can allow us to upgrade the existing design to overcome any operational deficiencies.

Various methods used to achieve the correct monitoring data are as follows;

Various methods used to achieve the correct monitoring data are as follows;

- Oil Debris Analysis

- Vibration Analysis

- Laser Alignment

- Thermal Imaging

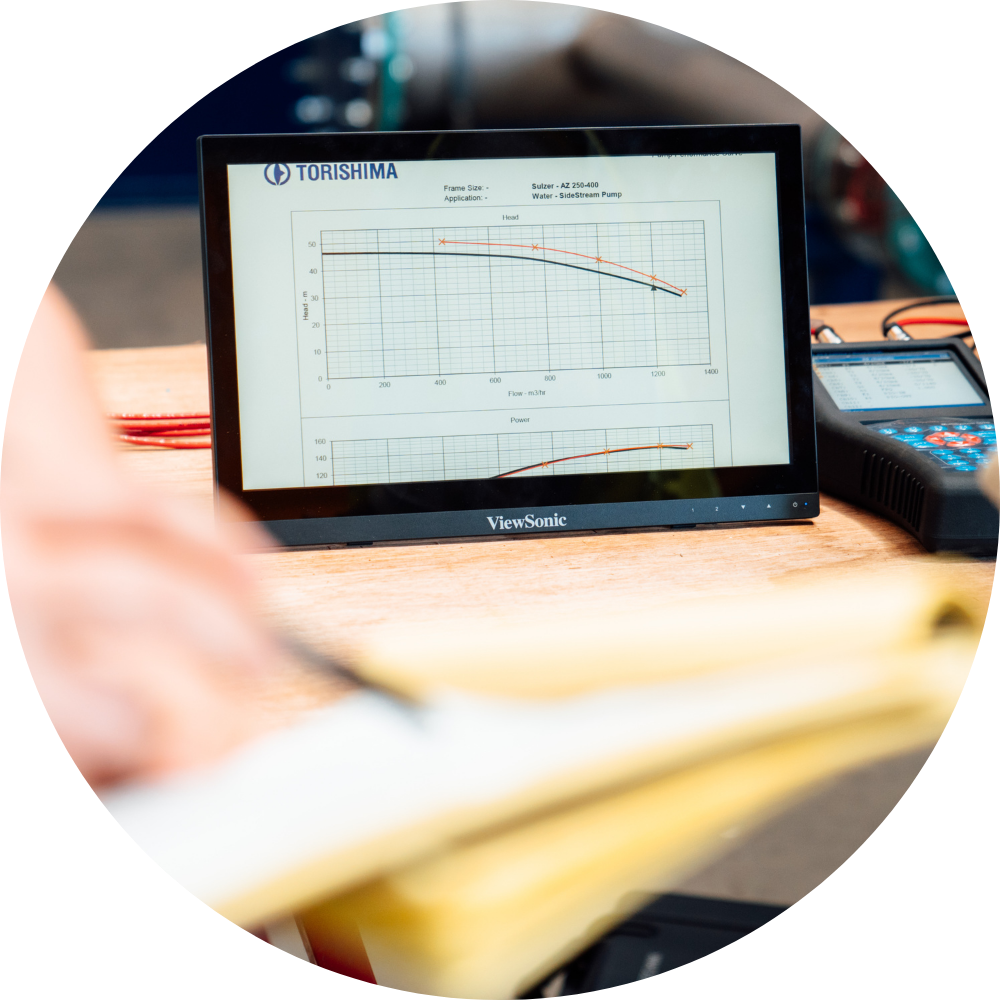

- Thermometric Pump Testing

Condition Monitoring Benefits:

- Asset condition check in real-time

- Prevent unscheduled downtime

- Reduction in operational costs

- Planned preventative maintenance

- Reduced energy costs and carbon emissions