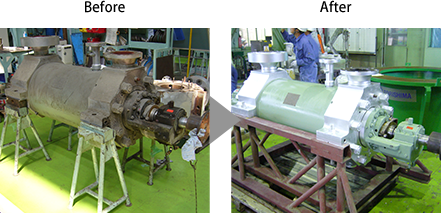

As a premier engineered equipment supplier, Torishima is committed to providing the highest quality aftermarket service. As a result of this, TSSE has developed an engineering process known as REDU (Re-Engineer Design Up). This process has been designed with plant operators in mind, who are experiencing issues related to poor performance, equipment obsolescence, or a general difficulty in obtaining spare components, critical or otherwise.

Failure to source critical spares at reasonable cost and with acceptable lead times has the potential to disrupt operations and negatively impact profitability. The benefits of REDU are considerable and can yield substantial operational and cost benefits.

Taking a worn or broken component, using 3D measuring equipment and in-house design capability TSSE can either re-engineer the part to the original design or, in most cases, improve upon it.

Torishima REDU will capture the geometry of components and then work back, taking into account any wear and tear, to develop manufacturing drawings, thus allowing replacement parts to be produced.

The bespoke engineering solution REDU offers therefore has a host of advantages, both technical and commercial;

|

|

|

|

|

|

- Improved Component Lifespan

|

|

|

|

|

- Spares for Obsolete Equipment

|

|

|

|

|

REDU provides customers with a unique opportunity to upgrade their existing equipment, acquiring components specifically tailored to the operational requirements, along with a catalogue of spares available as required, by making use of our combination of the latest technological advances and experience in the industry.